I knew the history of this car as for the last four years it has been parked next door! The previous owner had taken the car to the garage on a regular basis, on at least of half a dozen occasions, with no success.

So now it was up to me to sort out the issue. The problem had made the car all but un-sellable as a trade-in, since no dealer wanted to take on board the risk of an expensive fix for its new owner.

This web page details the path I took to locating the problem.

It taught me an awful lot about fuel injection system status (I already knew the basics of how it worked), taught me what looks right and what does not and taught me once again (see the Renault page) that you can have all the diagnostic tools in the world, but if you don't know how to interpret the data, they are worth 'Jack s&%*'.

"Testing, testing, testing."

After the expensive experience of having a dealer read an engine fault code on my Vauxhall ("That will be 70 pounds sterling, sir.") I had decided to equip myself with the ability to do it myself. The Vauxhall Vectra used an older software program called 'Vauxcheck' from Gendan.

The hardware used with this is an Elmscan 5 USB interface. Note that mine was cheaper as it came with a light-weight version of the software shown.

"Measure twice - cut once." (Well used woodworking term).

Although I had a suitable connector to fit the Volvo's ODB socket, it was obvious that the software would need to be replaced.

A quick e-mail to Gendan and I confirmed that their 'Engine Check Pro' software would work with the Volvo S60's electronics.

Downloading and installing it took no time at all and the e-mail with the code arrived on a Saturday morning, despite me not sending the payment until Friday evening (great service).

The next step was learning how to interpret the readings.

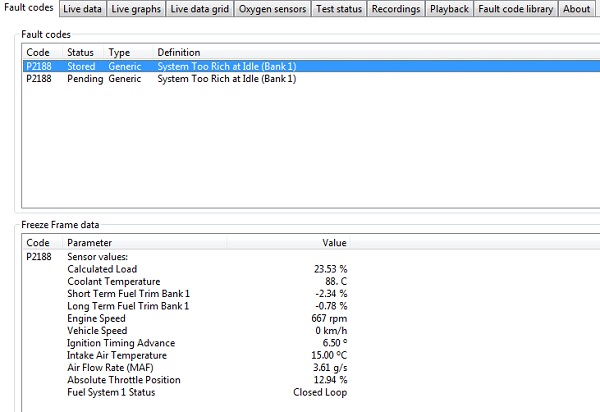

The above image shows the opening screen and the stored error code. "P2188 - System Too Rich at Idle (Bank 1)"

So what does all the information mean?

Calculated load = 23.14% - The engine is at idle and just pulling its own weight, so to speak.

Coolant Temperature = 91 degrees celsius - The engine was at normal operating temperature.

Short Term Fuel Trim Bank 1 = -9.38% - The ECU has reduced the amount of fuel it is supplying by 9.38% as the engine seems to be running too rich.

Long Term Fuel Trim Bank 1 = 3.91% - After a period of time, the short-term fuel trim adjustment is passed over to the long term fuel trim parameter.

The last value is an important one, 'closed loop' indicates that the ECU is accepting feedback from the O2 sensor, the one prior to the catalytic converter.

Open Loop - Closed Loop - Loop-de-loop!

Modern electronic (rather than mechanical) fuel injected vehicles use a 'map' to decide how much fuel to supply to the engine for any given load, speed, temperature etc. The engine uses this map exclusively when in 'open loop' mode, such as accelerating flat out.

During cruising conditions (pottling along nicely) 'closed loop' is used. During which the O2 sensor, Mass Airflow sensor (MAF) or Manifold Air Pressure (MAP) sensor (plus others) trim the amount of fuel to give the best possible fuel delivery (as decided by the manufacturer!)

Bank 1? That applies to Vee or boxer engines, where 'Bank 1' is the one where the number 1 spark plus is, in an in-line five-pot car like mine, you only have 'bank 1'.

Common Faults.

Despite the best efforts of the cars air filter, a certain amount of dirt will still get into the air intake system. This dirt can settle and bake onto the MAF sensors 'hot wire' or 'hot film' element and cause the sensor to give an incorrect reading.

In the case of my Volvo, it was hesitation off-idle and general bad behaviour and unresponsiveness in the lower rev range.

The MAF sensor and (I believe) the intake air temperature sensor, removed from the MAF housing.

A close-up of the thermistor which sends intake temperature information to the ECU.

The same sensor after cleaning with a can of electrical cleaner.

Close-up of the 'hot wire' element protector, again you can see the baked on dirt.

Note: - This is NOT the element, rather it appears to be a guard to stop you touching it. The element is deep inside and looks like a flat very fine plate.

After a quick spray, normal service is resumed (some of the spray apparently DID clean the sensor!). Snappy throttle response has returned, and for a lot cheaper than replacing the 300 pound sterling MAF.

"Groan!" (Some time later.)

Well, it doesn't take a rocket scientist to work out that the problem came back and this post is an update of what I have done (so far) to try and cure it. Yes, I am still working on the problem!.

One of the main problems I have come across is, I don't know how things are supposed to look, as I have never seen test feedback from a GOOD Volvo!

If you think this is an insignificant issue, then let me tell you about the O2 sensor diagnostics...

O2 Sensor Values.

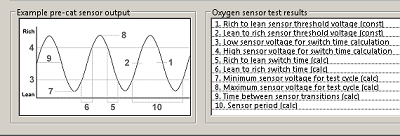

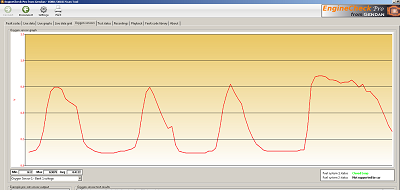

I am using Gendam's "Engine Check Pro" software to get information from my Volvo S60's ECU, on the oxygen sensor tab, there is a small image of what an O2 sensor SHOULD be doing. See below.

Being naive, I assumed that my O2 sensor was 'sluggish' as my 'curve' looked rather disappointingly slow. So I forked out the money for a replacement and fitted it. The result was the same. "HORLICKS"

Not satisfied with the progress, I tried the test of my wife's Ford Ka. "Success!"

To say the least, I was getting a little frustrated by the lack of progress, but "Hey-ho!" I am learning.

I have to admit, cleaning the MAF made the car FAR nicer to drive, with much less faffing about required at the traffic lights. So that was not a total waste of time and it did not cost a great deal. But the P2188 light is still bugging me.

As the previous owner is off work sick at the moment, I still have not received the service documents, so I know what has and what has not been done. Hence, I am still working in the dark.

Recap.

Everything I had seen on the Internet (so far) has told me that 'sensor 1' should swing back and forth between 0.9v and 0.1v and 'sensor 2 (after the catalytic converts(s) should be pretty steady. In fact, if it did swing, it would indicate a failed cat.

The astute amongst you will have already have spotted where this is going. I suddenly noticed that my sensors appeared to be the wrong way around!

As usual, I searched the Internet to see if there was a precedence for this and found this site. So this week, I have checked to make sure my O2 sensor 1 and sensor 2 have not been cross connected, which they have not.

It took me a while to notice the obvious difference between the Volvo and the Ford Ka's O2 sensor 1's read outs. Yes, mine is a 'Wide band Equivalence' model. And they do not swing back and forth like a narrow band one does.

Wide band sensor output.

The actual voltage of these remains quite stable and it is the current (amps) changing that forces the short term fuel trim to change.

Saturday 1st September 2012 - Back to the basics.

It has taken me a fair while to get around to changing the spark plugs and part of the reason is..."Which ones do I need?"

The Haynes manual says to use Bosch FR7DPP10's or FR7DPP+'s. I checked their spec on this site and they are both 19mm long. The trouble was, I could not find any. Not to mention the general census of opinion on the Volvo support sites is that the plugs of choice are Volvo original equipment.

That lead me to Volvopartshop.com.

I ordered a set for my 2006 S60, sure enough they were also 19mm long, but the joy ended when I removed the old plugs...and found they were longer. Quite a bit longer!

A further trawl of the Internet found 'partsforvolvosonline.com', they offer both the short plugs, and the long plugs.

Oh dear! It seems I have been sold the wrong ones.

Which is a great shame, as they looked pretty knackered to me. Replacing them would have been a good move.

Watch this space as since the plugs have been out, the light has stayed off. I did change the fuel filter (in front of the drivers side rear wheel arch) and take the fuel tank purge valve connector off and put it back on again, under the inlet manifold, access from the air filter side.

So far this week the light has stayed off. Fingers crossed. I am not holding my breath!

Wednesday 5th September 2012.

The bad news - I started the car to drive home from work and the engine yellow warning light came on again. "Ho-hum."

The good news - I e-mailed Volvopartshop.com and they have issued me with an RTM number, so I may yet get my money back for the wrong ones. On that basis, I have ordered the right ones from them.

Sunday 23rd September 2012.

Well the replacement correct plugs have arrived and I have been given a refund by Volvopartshop.com, top marks to them for being customer focused. They will of course benefit in the long run, as I have plans on replacing the 'positive crankcase ventilation' oil catch tank and its pipe work, plus the thermostat, which appears sluggish at best.

The engine is MUCH smoother with the new plugs fitted, but there is still the issue of the 'Too rich at idle' warning.

(Saturday 29th September 2012.

I have ordered a Positive Crankcase Ventilation (PCV) oil trap box and replacement hoses, as well as a replacement thermostat. The latter because the car is taking an age to warm up.

I will add details later, but this little snippet may well help someone this weekend.

Under the starboard side of the intake manifold (cam belt end) is a 19mm banjo bolt the secures the PCV suction tube to the intake manifold. Undo this and if oil drips out, you have a blocked PCV box and you need to sort this out.

I started mine today and it is well clogged.

Sunday 30h September 2012.

Top tip - use gaffer tape to blank off all the holes in the slam panel, by habit you will probably rest tools on it and they WILL drop down a hole!

I replaced the oil separation box and its hoses, re-fitted it and the intake manifold, then dropped a manifold bolt down....behind the oil box!

I should add that my intake manifold has four LPG injectors and their pipe work, so getting the bolts back in is a real pig.

So much so that I did that trick twice!

After a fourteen-hour weekend, I gave up and borrowed the wife's car to get to work on Monday.

Tuesday 2nd October 2012.

Thankfully the weather has held off (it is now raining, at 8:30pm) and I have got it back together, coolant changed, road tested and ready to see if it has made that important difference.

As an aside, I decided to clean the old oil trap with petrol and then open it to see how effective the cleaning had been. If you are doing this to keep your car? My advice is 'replace' - every time.

In the foreground is the detached thermostat hose connection, the small black hose from this goes to the underside of the intake manifold where it keeps the oil fumes heading to the turbo intake area from freezing. Top left is the brown petrol injector and just to the right of this is the brass fitting which injects the LPG into the intake runner. The oil flat platform just up from bottom centre is the top of the dreaded oil separator box.

With the oil separator box removed, the lower opening can clearly be seen to be clogged.

"Eeew!" Not what you want to see. The stick in the background was cut to length so that I can check the brakes lights on the old Vectra.

The oil drains back into the sum via this hole. I had to 'drill' it out with a 10mm drill, by hand, to clean out the crud.

At least this way there was a good chance of not pushing the muck into the engine! My only worry was, 'Is it blocked further in?'

This should once have been premium grade oil. My guess is it was cheap as chips (chip) oil!

Checking all along the pipe work, it became clear that some pipe work had reached the end of its useful life. I managed to repair it by sliding a piece of rubber vacuum hose over this.

It would be stupid not to check the throttle body while the intake was off, cleaning this up should help things.

'Curious George' cut the oil separator tank in half after giving it a quick wash out with degreasing agent. Note: - Some small black specs are from the cutting process.

But rest assured that this mess is not. No amount of 'cleaning' is going to get rid of this. Replace the box, it is your ENGINE for heavens sake.

If some of this gets back into the oil system its curtains for your lovely turbo, camshaft and possibly crankshaft bearings.

Saturday 3rd November 2012.

Despite all this work, the car still came back with the same 'check light' even after allowing a few weeks for things to settle down.

The search goes on.

Thursday 15th November 2012.

I now have a new MAF on order from 'The Tinternet', rather than risk wasting money on a Chinese 'replica' I went for a genuine Bosch item, another Ebay purchase. One last shot at fixing it before I had it over to the men in white coats with 1,000 pound sterling 'scopes.

While I am updating, I thought it worth mentioning the fuel consumption figures. Of course they will mean nothing if you do not understand how I drive. My daily commute takes me along a pretty busy 'A' road, through a couple of villages and then onto a ten mile stretch of dual carriageway, before sitting in traffic for three miles.

The drive takes about an hour to do the 40 miles, I am not against over-taking, but there is little to be gained when there are another twenty cars in front of this one!

Fuel consumption at the pump is 27-28mpg (that is both petrol, which the car warms up on and LPG combined) while the trip computer reads around 33mpg. This week I have stayed at 60mph along the dual carriageway and that figure has increased to 36mpg at the dash. So we shall have to see how that has affected the pump numbers.

The previous owner got 28mpg at the dash!

Hopefully the new MAF will sort out the hesitancy at idle when cold and also cure the P2188 fault code. Maybe then I can get the pump numbers up to the dash numbers? Now THAT would be a result!

Saturday 17th November 2012.

The new MAF arrived this morning, very please with that as I ordered it on Thursday evening. Fitting it was easy. I have perfected the art of removing the intake system over the last months!

Checking the air filter, it has taken a real hammering from the harvest dust from a few months back. The lower half of the air box was coated with a thin film of what looked like oil, but was actually moist dust. So that got a wipe out as did the hose towards the front grill.

Looking back after re-fitting the air box lid, I recalled that the rear locating lugs were not seated correctly when I bought the car, so this fine dust would possibly have by-passed the filter had trashed the MAF.

With the old MAF out, I carefully wiped the 'down-stream' side of the MAF grill with a tissue and a fair amount a black dust came off. "Mmmm!"

So with everything in place it was off down the road to data log the changes.

First impression, the car did not appear to be as prone to hesitate (but then after 10,000 miles of doing it, I am paranoid). Second, the car did not 'hunt' like it did before, but this was not a huge problem, I have noticed it more because it DOES NOT do it, rather than it did!

The car also appeared to warm up quicker. Over-all it felt OK. So what did the software say?

I ran the car at idle when I got home, the MAF value was 2.30 to 2.38 over a 100 second period. That is MUCH lower than with the old MAF, which usually recorded around 3.5 to 3.8 g/s. that is between 62% to 67% of the old recorded airflow at idle. Or put another way, the engine thought it was getting 52% to 59% more air than it was.

Fuel trim from cold (having re-set the computer) was pretty good, a spike of -22, then one of -19, then a third of -16. Where as before it would be banging off the -25 end stop pretty often for the the first 280 seconds. Those figures were for +12c (historic) and +9c today, so it is not like the previosu value was a colder start!

One thing I did notice during the post run warm idle test, switching from LPG to petrol caused a pretty big negative fuel trim, indicating that this will need attention. LPG had settled at -17 STFT and +3 LTFT, switching brought STFT back to -7. Add that to the +3 LTSF and we have a mean -3. "I am happy with that!"

The quick test was pretty positive, but next week will give it a 'yeah or nay'.

Saturday 24th November 2012.

Well it is one week and about 250 miles on from when I fitted the new MAF. I am quietly confident that the problem is now solved, but it is still too early to be dancing in the rain to celebrate.

One week of commuting has been passed without incident, so I may have found the cure. Check back in a month to be sure.

Sunday 12th may 2013.

Well as you can see from the date stamps, I have not been bothered by the fault since I changed the MAF.

I have however moved the issue elsewhere and that is totally my fault, as I had the LPG system installed when the engine was not running as it should. So now the LPG system is out of tune just off idle.

I should add that if I run the car on petrol, the engine warning light goes out. So as far as I am concerned, the problem was solved by replacing the Mass Airflow Sensor (MAF sensor).

An added benefit is that the oil consumption has been greatly reduced by the replacement of the oil trap under the intake manifold. It had been using about one litre every 750 miles. That has decreased to around a litre every 5,000 miles. A job well worth doing.

Last updated: 10/01/2020

All pages created with Notepad++ unless otherwise stated.